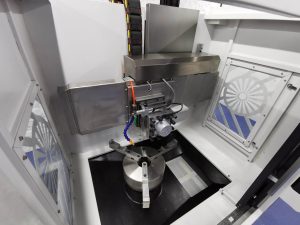

Alloy Wheel Diamond Cutting Machine

At Ayce Solutions, we are proud to offer the latest technology for alloy wheel cutting. Our CNC machines deliver fully-optimised wheel curves with just two clicks, made simple with a new touch screen interface. Submit an enquiry using the link below to find out more.

Achieve Outstanding Results

Diamond cutting is the process of skimming the top layer of the diamond cut surface of the wheel to remove the damage. This process, when done properly, leaves a diamond cut effect on the wheel, which is achieved using a diamond cutting lathe, sometimes called a diamond cutting machine.

Cutting-Edge Technology

Our purpose-built alloy wheel lathe incorporates a user-friendly, graphical, multi-touch interface for simplified probing and cutting processes. Other new features include:

- Faster probing cycles using the automatic touch probe

- Lip profile adjustments for removing curb damage

- Electric turning turret

- 2 button optimising

- Spindle stop feature for dry runs

- WIFI enabled remote support

- Remote MPG handwheel for manual mode

Our specialist wheel lathes also include an improved built-in wheel profile optimisation software. This means that with two clicks, a wheel is optimised and ready for cutting. They truly are the most user-friendly machines on the market, with fully customisable edge profiling, lip cutting and much more.

Book a Demonstration

If you are interested in a demonstration, please get in touch or fill in the form below and a member of our team will be in touch.

Diamond cutting Wheel Lathe - Key Features

|

Easy to use touch screen interface – our new style touch screen interface has been refined to be easier than ever |

|

|

One Touch wheel optimisation – after the probing cycle, press smooth and the system optimises the wheel curve for you. No more manual optimisation |

|

|

Cuts up to 30″ wheels |

|

|

Automatic digital probe |

|

|

Automatic 4 position turret |

|

|

Automatic Electric pump lubrication |

|

|

AirJet system – air is blown across the wheel to stop the swarf getting caught around the tool and scratching the wheel |

|

|

Multiple cutting cycles automatically |

|

|

Tracking of total amount cut |

|

|

Remote WiFi support |

|

|

Full UK-based technical support |

|

|

12 months warranty included |

|

|

up to 2 days onsite training included with every purchase |

|

Electric Turret

Airjet System

Multiple Cycles (speeded up)

Can I See the Machine in Action?

To see how our diamond cutting machine operates, take a look at our video below for a brief demonstration of its capabilities. Alternatively, contact us using the form below to book a demonstration.

Get In Touch

Submit a request for a demonstration of our CNC Diamond Lathe by filling out the form below, or place an order for a machine today.

FAQs

How Does a Diamond Cutting Machine Enhance Alloy Wheels?

There are a number of benefits to using a CNC diamond lathe for enhancing alloy wheels, including:

- Effective Restoration – Diamond-cut alloy wheels can be effectively restored to their original finish using a wheel lathe.

- Maximum Efficiency – Diamond cutting machines are not just extremely effective, they are also efficient.

- Improve Appearance – The distinctive diamond-shaped pattern can be successfully restored to a wheel’s surface with the help of an Ayce Solutions diamond cutting machine.

- Maintain Performance – Restoring alloy wheels using a CNC diamond lathe ensures that the performance (and value) of alloy wheels can be maintained.

Can the Machine Be Operated by Non-Experts?

Included with every purchase of our CNC Diamond lathe is a two day training course to ensure that up to two members of staff within your business are able to effectively operate the machine. While the machines are simple to operate, it is vital that they are operated by a member of staff with the correct training. Find out more about our available training here.

How Long Does It Take to Complete the Cutting Process for One Wheel?

Using our diamond cutting lathe, a standard alloy wheel can be prepared in up to five minutes. With more experience using the machine, this time can be reduced even further.